Case Studies

Energy Optimization for Factory A

Reduced energy consumption by 25% through modern electrical solutions and automation.

Outcome: Lower costs and more sustainable operations.

Motor Upgrade for Manufacturing Line B

Replaced outdated motors with high-efficiency ones to improve production efficiency.

Outcome: Increased throughput and decreased downtime.

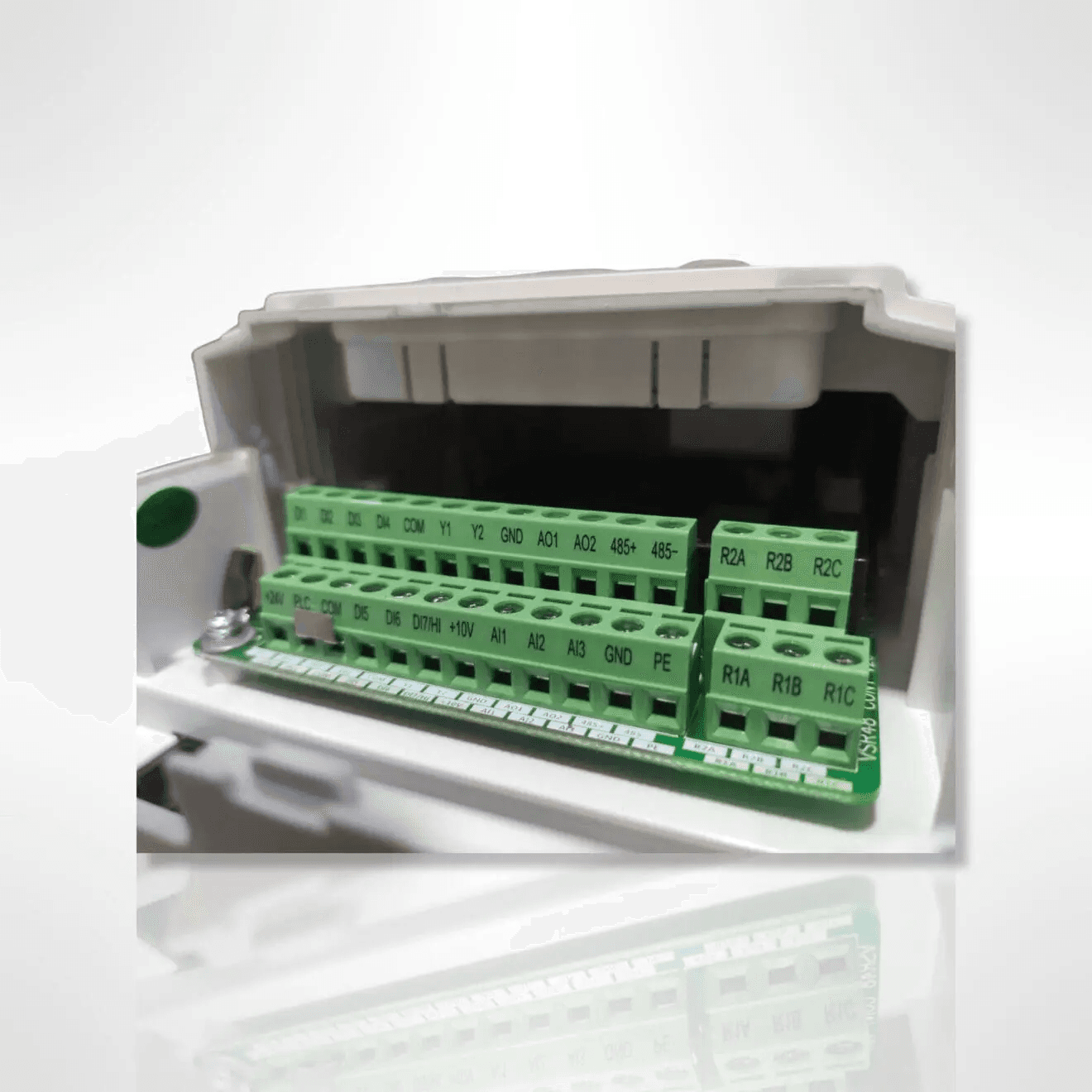

Custom Electrical Panel Design

Designed and implemented custom panels for a large industrial plant.

Outcome: Enhanced safety and simplified maintenance.

Preventive Maintenance Program

Introduced preventive maintenance schedules for critical equipment.

Outcome: Reduced unplanned outages by 40%.

Automated Control System Implementation

Implemented automated control systems for better monitoring and control.

Outcome: Optimized production efficiency and real-time monitoring.

These case studies demonstrate our expertise in providing practical, cost-effective, and innovative solutions for industrial challenges. We are committed to helping our clients optimize operations, improve efficiency, and achieve their business goals.